SOLAR POWER FROM THE SEA

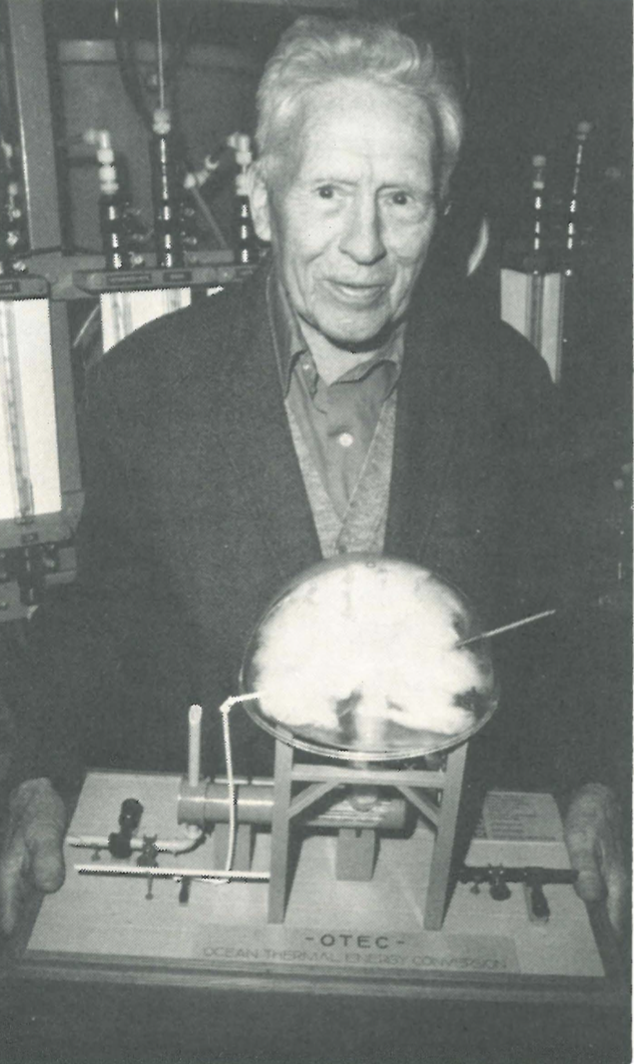

OTEC, Ocean Thermal Energy Conversion, was a main focus of Shamcher’s work after WWII, when he brought the system from France to the US. Below is an article Shamcher wrote describing OTEC, which is more timely now than ever.

Shamcher’s book, Planet Earth Demands focused directly on energy needs and OTEC. In his work over the decades he produced many working papers, energy overviews and presentations. Mansur Johnson’s memoir is also of direct interest here.

OTEC HISTORY (OTEC means Ocean Thermal Energy Conversion)

Ocean Thermal Difference, the difference between surface and deeper layers as a source of power, has been recognized for more than a century. In 1881 an American engineer, Campbell, two Italians, Dornig and Boggia and a French physicist, D’Arsonval, proposed a closed cycle Ocean Thermal device. The warm surface water would heat and cause evaporation of a “working fluid (alternative fluids were suggested) which would pass through a turbine, thereafter being condensed by cold water pumped up from deep layers, and again fed into the evaporator.

The first to build practical plants was a pupil of D’Arzonval, the French engineer George Claude, member of L’Academie des Sciences, of the French Society of Civil Engineers. He won the fiftieth anniversary medal of the American Society of Mechanical Engineers. He chose the “open cycle system” in which the ocean surface water itself evaporates and drives the turbine, and rejected the “closed cycle”, of which he said in a talk to American engineers 22 October 1930(1.):

“Manifestly, such a solution is burdened by a number of inconveniences, one of them being the extra equipment for and cost of the working fluid and another the necessity of transmitting enormous quantities of heat through the inevitably dirty walls of immense boilers…. The sea water itself contains all that is needed for the direct utilization of such small temperature differences.”

Claude ran a small experimental device before fellow-members of l’Academie des Sciences in Paris, then build a larger plant at OUGREE in Belgium, which, in his words, “Made my virulent opponents hold their tongues.” His one-meter diameter turbine generated 60 kilowatt at 5000 rounds per minute with a total ocean thermal difference of 20 degrees C. This proved the thermodynamic viability. “It remained to be seen how the plant would function in the ocean, how pumping cold water form deeper layers would influence neighboring layers and whether foaming would drastically decrease efficiency or break the turbine.

Claude moved his Belgian plant to Cuba. A two feet diameter pipeline would have been sufficient to supply his turbine with the proper amount of steam, but would have caused the cold water to be warmed before arriving at the condenser and would have incurred intolerable friction losses. A pipeline of two-meter diameter was built — and lost in a storm. A second pipeline was also lost. A third pipeline was built and successfully laid. The plant ran for eleven days, producing 22 kw on a turbine much too small for the other components of the plant, but Claude was operating on his own money and that of a few friends, and could not afford a new turbine. The basic function was nevertheless proven and, in the opinion of these resourceful enterprisers, should have been followed by prototypes and commercial plants.

In 1931 a French maritime company built a pilot plant for shipboard use at Le Havre, described by H. Brillie in GENIE CIVIL for 21 June 1931 (2.) This plant, using ship engine wastewater as warm water source and ocean surface water as cold water source produced fresh water with as little as 1-2 parts per million salt and a power expenditure of only a fraction of conventional plants, according to the report. Gossipers claim the plant was killed by people who wanted to sell more fuels to ships.

In 1941 the French Government became involved and in 1942 ENERGIE DES MERS was formed, a semi-official company for researching and building OTEC plants (3,4). In French laboratories and on a chosen site at Abidjan in West Africa research was conducted for example on the effect on neighboring layers when huge amount of cold water was removed by pumping. Only the closest 1ayers were found to be involved.

Mindful that Claude had lost two pipelines, the manufacturing and laying of the cold water pipeline were carefully planned and carried out. This pipeline was considered the only new and unproved component in the plant and therefore given major attention. The line was left in place for six months for study of corrosion/biofouling. The area between low and high tide was found particularly vulnerable. For current OTEC ships, with the cold water pipeline entirely under water, this would be irrelevant. In laboratories in Dakar and in France proper research was conducted on general evaporator and condenser problems, including air-and-gas removal from seawater under evaporation. An entire plant was designed but never built.

In 1947 and 1948 the undersigned studied the French work, returned to the States and became involved with the University of California and its newly established Sea Water Conversion Laboratory. In 1951 Professor Everett D. Howe, founder and first director of the Sea Water Conversion Laboratory, obtained State funds, later Federal funds, from the “Saline Water Office” that had been established when Dr. James Hofman of the National Bureau of Standards demonstrated in Congress two sma1l thermal machines built in my presence on the pattern of the French.

The University of California built and tested plants, all open cycle, since the University wanted desalination, primarily. In the open cycles, desalination is achieved with no additional cost. A laboratory plant was built and tested by Dr. Lev Akonjanoff. Its main feature was a two-quarts pyrex glass kettle. This vessel is kept in a stove at constant temperature, to avoid losses by condensation on the glass wall.

Tests were made with

a) batch distillation with constant temperature and pressure,

b) batch distillation with constant temperature and varying pressure,

c) flow-distillation with constant temperature and pressure,

d) flow-distillation with constant temperature and varying pressure.

This laboratory-sized plant was built and tested in the Hesse Hall of the Berkeley campus. At the Sea Water Conversion Laboratory of the Richmond Field Station was simultaneous built the so-called ‘first low-temperature difference plant’ consisting of an already available 4.5 feet long and 30 inches diameter cylindrical evaporator plus condenser, pumps etc. It was scheduled to produce 2,000 gallons desalted water per day and no power.

After this plant had been tested for a variety of possible conditions, our ‘second low temperature difference plant’ was designed and built. Fu.11.d~ had n0′-1 been made available for suitable hardware. This plant was scheduled to produce 2,000 gallons per day desalted water and no power. After this plant had been tested for a variety of possible conditions, our second low temperature difference plant was designed and built. Funds had now been made available for suitable hardware. This plant was scheduled to produce 10,000 gallons per day desalted water plus as much power as our available General Electric turbine would seem willing to offer. This turbine had been used in an aircraft air conditioning unit. The evaporator had been supplied with three windows and inside lights, so that the flash evaporation procedure could be observed. The seawater was seen to explode in a myriad of drops the moment it entered the evaporator. The prior idea of drip-trays, over which water was supposed to flow in sheet-like formations, was proven invalid. This again may be one reason why our yields often were higher than formulas predicted.

Dr. Akobjanoff and Mr. Beorse conducted independent studies of evaporation rates related to then existing formulae. Yields in the University plants varied from 2 to 189% of predicted values. Dr. Langmuir, co-author of the Langmuir-Knutsen formula, saw the reason for this in that essential factors had not been included in the formulae, during a discussion with Mr. Beorse in 1955. Tables, showing yields of desalted water and power produced at the University plants, are available at the University and/or Sea Water Conversion laboratory. One table, showing cost, estimated and confirmed, of various desalting methods, indicates that desalting cost for a Low Thermal Difference Plant is lower than for all other methods and lower than the then-goal for municipal water (85 dollars versus 125. dollar per acre foot) but higher than the irrigation goal (40 dollars).

Commercial Design

On the basis of this testing of three plants, the University designed a desalting plant for the canyon near La Jolla and the Scripps Oceanographic Institution. It was scheduled to produce five million gallons fresh water per day. This plant would have no turbine. The total temperature difference in the winter was l6°F, not enough for power production but enough to desalt water at a lower cost than any then or later developed system, since this small thermal difference provided distillation under vacuum.

Additional energy for pumping, etc, would come to 24 cents per l000 gallons while fuel-fired plants require from three to four times as much energy. With the addition of maintenance cost, total cost comes to 28 cents per 100 gallons, not including amortization and interest, which changes from site to site.

A smaller plant would mean a greater relative cost for the cold water pipeline and for maintenance, so the total cost would be higher. Firm bids were obtained for all components, including two million dollars for manufacturing and laying the cold water pipeline. This one job was upped to three million in our estimate. We tried to be equally conservative for other components. The estimated cost of the entire p1ant was six million dollars. People not familiar with our research and estimate preferred a one and half billion dollar Feather River project – valid, in a sense, at least, while water supply in Northern California was ample. It isn’t any more. The subject plants may still be built, all over Southern California.

The University of California and Energie des Mers

Following Mr. Beorse’s study at Energie des Mers in France in the late forties, the General Director of Energie des Mers. Andre Nizery visited the University of California and gave a seminar at the Berkeley Campus in March 1954(10). Andre Nizery was also deputy Director of the huge semi-public corporation,”Electricite de France” which supplies the French with electricity and other forms of power. Professor Everett D. Howe of the University, along with David Jenkins, then director of the Saline Water Office of the US Department of the Interior visited Energie des Mers in Paris and Abidjan. Mr. Beorse again visited Energie des Mers in 1957, 1959, 1963 and 1973, this last time on occasion of the passing of M. Christian Beau, who had been General Director of Energie des Mers after Andre Nizery’s death. M. Beau had also been head of Frances public works.

All personnel of Energie des Mers were convinced that they had the obvious solution to the world’s energy problem. Their research had confirmed their brightest hopes. The winds or politics in France favored nuclear energy.

Throughout the years until today the University of California continued specific research on heat transfer, heat exchangers, de-aeration, evaporator characteristics, preventing carry-over of water droplets into the steam flow, scaling, corrosion, biofouling.

In June 1957 Professor E.D. Howe reported to ASME (ll). From 1960 Hilbert and James Anderson, a father-son engineering team, took up a serious study of a closed cycle plant and acually built a small sample.

In the seventies, with the soaring oil prices, the National Science Foundation took up the matter, asked for studies, and received voluminous reports, first from the University of Massachusetts at Amherst, principal investigator Professor William E. Heronemus, a former Navy Captain who had been in charge of vast ship-building efforts. In rapid succession followed the John Hopkins Universitys Applied Physics laboratory, the Carnegie-Mellon University, the Universities of Texas, Hawaii, New Orleans, Florida. — and substantial industrial firms, Lockheed, Bechtel, TRW, and of course the Andersons’ Sea Solar Power, Hydronautics, Batelle, Allied Chemical Corporation – thousands upon thousands of pages promising a multitude of types and all of them emphasizing the immediate readiness of this technology and the wholly benign ecological effects. Cost estimates vary from $400 and up per Kilowatt built and of course the fuel is free.

If only two percent of the power available in the Ocean Thermal difference were utilized we would have many times as much energy as the world now needs.

Bryn Beorse,

University of California.

19 September 1977

References

1. Power from the Tropical Seas. By George Claude, “Mechanical Engineering”, December 30 1930. Report of a lecture given at ASHE NY October 22 1930.

2. Genie Civil, 21 June .1931: Article by H. Brillie on shipboard OTEC plants.

3. Rapport General. By C. Beau: Question VIII: Utilisation de I’ energie thermique. Mid-June 1956.

4. Travaux Anciens et Recent sur 1 ‘Energie Thermique des Mers. By M.Salle & A. Capistan. Mid-1956.

5. Vacuum Distillation in a Laboratory-Sca1e Thermal Difference Plant. By L. Akobjanotf, B. Beorse, E.D. Howe. Ue report Oct.l 1955 Ser 75 Issue 3.

6. Vacuum Distillation of Water. By L. Akobjanoff’ & E.D. Howe, Research”, June 1956 pp 220-226.

7. Progress Report to the State of California Legislature. March 1 1955, Ser 75 issue 2.

8. Progress Report for Calendar Year 1956. March 1 1957 Ser 75 Issue 5

9. Report on Vacuum Evaporation Studies. By Bryn Beorse March 1 1955.

10. A Report on Utilization of the Thermal Potential of the Sea for the Production of Poer and Frech Water. By Andre Nizery, Director General of Energie des Mers, Deputy Dierctor of Electricite de France. Seminar given at the University of California at Berkeley March 1954.

11. Vacuum Flash Distillation of Sea Water. ASME paper No. 57-SA-92. Lecture delivered by Professor Everett D. Howe at ASMEs semi-annual meeting June 9-13, 1957.

The above references are limited to work done before 1960. Subsequent publications are well known and easily available, from the National Institute of Technical Information, from ERDA, Washington DC 20545 and fro, the firms and universities under contract to ERDA, such as Hilbert Anderson, Lockheed, Bechtel, TRW, Westinghouse, Hydronautics and the Universities of Massachusetts (Amherst), John Hopkins (Applied “Physics Laboratory) Carnegie-Mellon, Hawaii, Texas, California and many other OTEC participants. —